Membrane filter presses are an essential tool in various industries, including water treatment, wastewater treatment, and food processing. They are used to separate solids from liquids, and their efficiency and effectiveness make them a popular choice for many applications. But have you ever wondered how a membrane filter press works? In this article, we will explore the role of membrane filter plates and how they contribute to the filtration process.

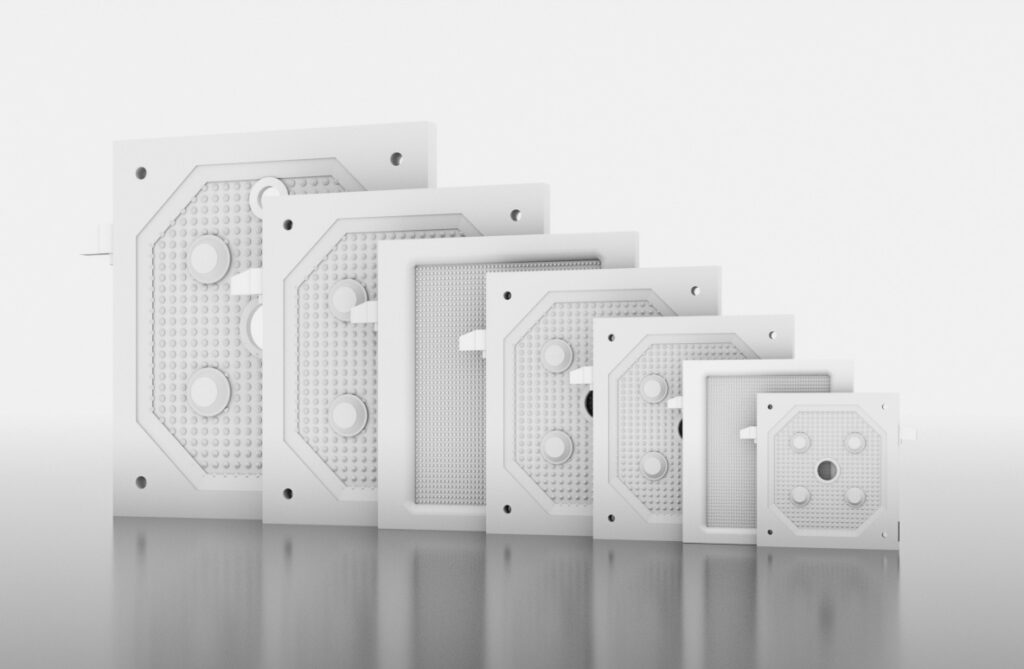

Membrane Filter Plate

The membrane filter plate is a critical component of a membrane filter press. It is a thin, flat plate made of a porous material, such as polypropylene or polyester, with a specific pore size. The plate is designed to allow liquids to pass through while blocking solids and other impurities. The membrane filter plate is placed between two plates, creating a sandwich-like structure, and the liquid to be filtered is passed through the plate, leaving the solids behind.

The membrane filter plate has unique structure that allows it to filter out impurities effectively. The pores in the plate are uniform in size, allowing only particles smaller than the pore size to pass through. The plate also has a high surface area, allowing it to filter a large volume of liquid quickly and efficiently.

Types of Membrane Filter Plates

Several types of membrane filter plates are available, each with unique characteristics and applications. Some of the most common types of membrane filter plates include:

- Woven polypropylene plate: This is the most common type of membrane filter plate. It is made of woven polypropylene fibers that create a strong and durable fabric. The plate has a high filtration efficiency and is resistant to chemicals.

- Non-woven polyester plate: This type of plate is made of non-woven polyester fibers that are bonded together using a special process. It has a high filtration efficiency and is resistant to chemicals.

- Woven nylon plate: This type of plate is made of woven nylon fibers that create a strong and durable fabric. It has a high filtration efficiency and is resistant to chemicals.

- PTFE plate: This type of plate is made of polytetrafluoroethylene (PTFE) fibers. It has a high filtration efficiency and is resistant to chemicals and heat.

Advantages of Membrane Filter Plates

Membrane filter plates have several advantages over other types of filtration systems. Some of the advantages include:

- High filtration efficiency: Membrane filter plates have a high filtration efficiency, allowing them to filter out a large number of impurities from the liquid.

- Durability: The plates are made of durable materials that can withstand harsh chemicals and high temperatures.

- Low maintenance: The plates require minimal maintenance, making them a cost-effective option.

- Versatility: Membrane filter plates can be used in a variety of applications, including water treatment, wastewater treatment, and food processing.

Conclusion

In conclusion, membrane filter plates are a critical component of a membrane filter press. They are designed to filter out impurities from liquids, and their unique structure and properties make them an effective tool in various industries. Several types of membrane filter plates are available, each with unique characteristics and applications. By understanding how membrane filter plates work, we can appreciate their importance in ensuring the quality of our water and other liquids.